BACTSTERTM

Airborne Low Intensity Multi Frequency

Ultrasound (ALIMFUSTM) Microbe Sanitizer

BACTSTERTM is a paradigm shift from the conventional methods and approaches to microbial sanitation.

Chemical Based Fumigation

Disadvantages

- Toxic To Human Body

- Harmful To The Environment

- Occupational Exposure During The Process

- Non-occupational Evacuation During The Process

- Settling Period Post Fumigation

- Recurring Cost of Chemicals.

Chemical Based Fumigation

Disadvantages

- Toxic To Human Body

- Harmful To The Environment

- Occupational Exposure During The Process

- Non-occupational Evacuation During The Process

- Settling Period Post Fumigation

- Recurring Cost of Chemicals.

Ultraviolet Radiation Sanitation

Disadvantages

- Needs Human Evacuation During Exposure

- Cannot Sanitize Large Areas

- Sanitizes Only Exposed Areas (Line of Sight From Source)

- Limited Life of UV – Lamp.

Ultraviolet Radiation Sanitation

Disadvantages

- Needs Human Evacuation During Exposure

- Cannot Sanitize Large Areas

- Sanitizes Only Exposed Areas (Line of Sight From Source)

- Limited Life of UV – Lamp.

The Science Behind BACTSTERTM Ultrasonic Sanitizer

BACTSTERTM uses a specially designed ALIMFUSTM technology (Airborne Low Intensity Multi Frequency Ultrasound) which can engulf bacteria from all directions and destroy them.

BACTSTERTM Working Principle

Surface Test Efficacy – Various bacteria

Surface Test Efficacy – Fungus

* All tests conducted at Bureau Veritas Labs. The results may vary subject to environmental conditions of your site.

Wooden Surface – Bacteria Test

Cloth Surface – Bacteria Test

Food (Apple) – Bacteria Test

Glass Surface – Bacteria Test

Painted Wall Surface – Bacteria Test

Steel Surface – Bacteria Test

Metal Surface – Bacteria Test

Plastic Surface – Bacteria Test

Granite Surface – Bacteria Test

POP Surface – Bacteria Test

* All tests conducted at Bureau Veritas Labs. The results may vary subject to environmental conditions of your site.

BACTSTERTM Comparison With Existing Sanitization Methods

| Features | UV/ Fumigation | Chemical Treatment | BACTSTERTM Ultrasonic Microbe Sanitizer |

| Human Presence |  |

|

|

| Non Hazardous |  |

|

|

| Non Toxic |  |

|

|

| 24 X 7 |  |

|

|

| One Time Investment |  |

|

|

| Control Air Bacteria |  |

|

|

| Control Surface Bacteria |  |

|

|

| Eco Friendly / Green |  |

|

|

| Life | UV Lamp dependent / Routine Process for Fumigation | Routine Regular Process & Human Intervention | 24 X 7 Active Protection |

Please note that BACTSTERTM is a standalone device and can also can be used as an adjunct method along with other modes of treatment available for microbial sanitation.

BACTSTERTM – Safe To Use

BACTSTERTM is produced strictly keeping in mind all safety aspects.

BACTSTERTM is made as per the guidelines / safety standards laid down by :

- American Conference of Governmental and Industrial Hygienists (ACGIH)

- International Commission on Non Ionizing Radiation Protection (ICNIRP)

- World Health Organization.

- International Radiation Protection Agency IRPA (Geneva)

- Bureau of Radiation and Medical Devices, Canada and many others.

These guidelines are published by INIRC on their website www.icnirp.de/ documents/ ultrasound. pdf detailing the exposure limits, frequencies, etc.

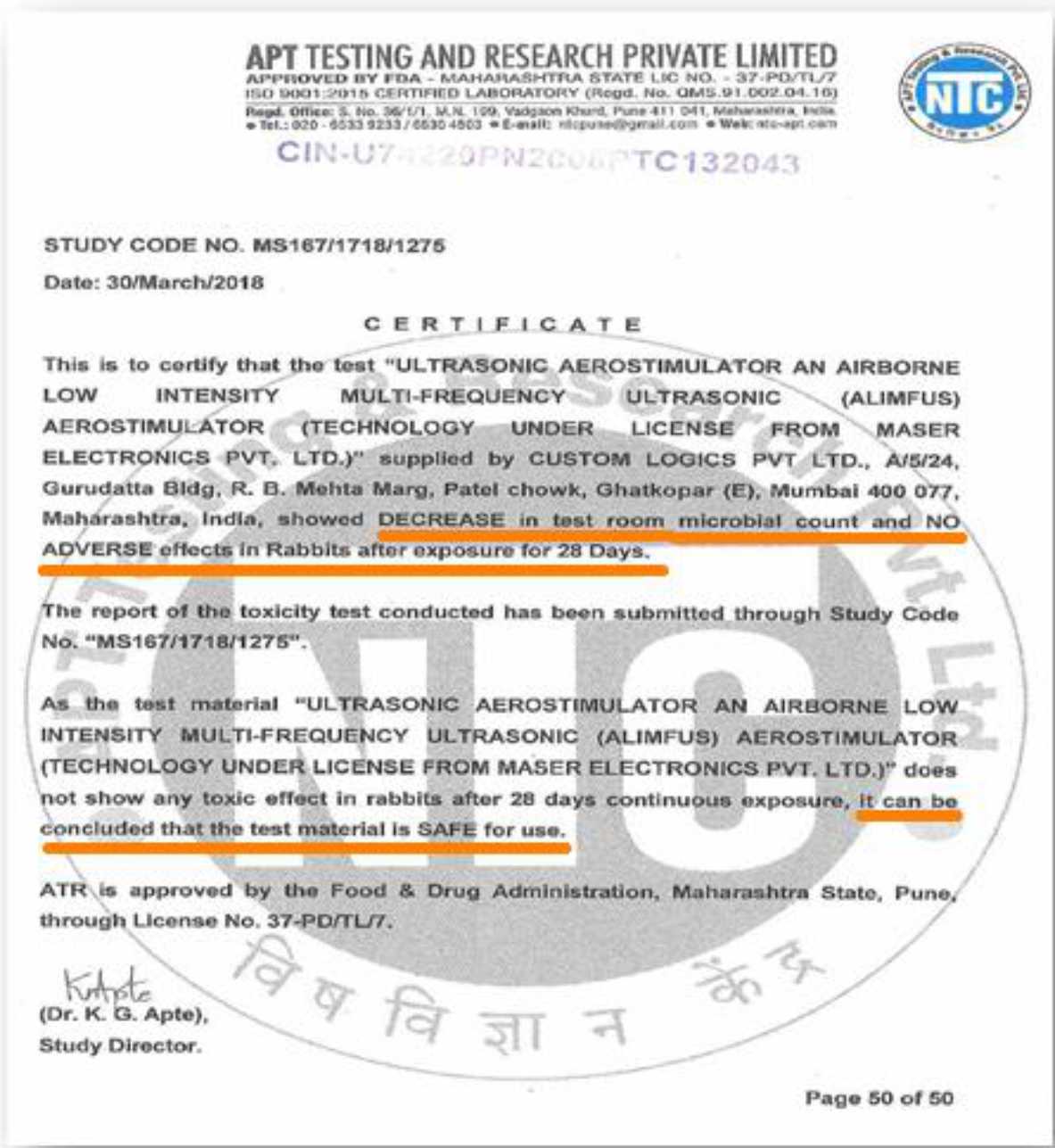

Clinical toxicity test report for BACTSTERTM performed at “FDA APPROVED LAB” APT Testing and Research formerly known as National toxicology center, PUNE.

ALIMFUSTM is the registered trademark of Maser. Maser has patented this technology under patent application numbers (Patent Ref No. 201821021401/201821021402). It also has design registrations for the product ultrasonic microbe sanitizer under design registration numbers (Design Application Ref. Nos. 306408/306409). Maser Electronics has sole rights to ALIMFUSTM technology and its related product designs.

Efficacy

BACTSTERTM has been widely tested for its efficiency at various local, international, government, and non-government laboratories like Haffkine Institute, SGS’s labs, APT Testing and Research and Bureau Veritas

Advantages of BACTSTERTM Ultrasonic Microbe Sanitizer

- A novel method for Microbial Sanitation

- Safe to use and environment friendly

- Non-hazardous and chemical free

- 24/7 operation in human presence

- No recurring cost

- Simple to use and install

Clientele

- Venkateshwara Hatcheries Pvt Ltd (Venkys).

- Vista Processed Foods Pvt Ltd (Indian office of the OSI Group Illinois USA. OSI is the premier global supplier of custom value-added food products to the world’s leading foodservice and retail food brands like Subway, Starbucks, Pizza Hut etc.)

- Kamaths Ourtimes Ice Creams Pvt Ltd (Naturals Ice creams)

- Everest Spices.

- Pune Municipal Corporation